Exploring the Crucial Functions and Advantages of Metal Foundries

Steel foundries offer a critical function in the manufacturing landscape. They transform resources into specific metal items for various markets. This procedure includes specialized techniques that assure quality and performance. The financial ramifications are significant, impacting neighborhood communities and task markets. As technology evolves, so do the methods within the market. Understanding these characteristics reveals much about the future of production and its function in sustainability. What exists ahead for metal factories?

The Role of Steel Shops in Manufacturing

Metal shops play an important role in the manufacturing industry by transforming basic materials right into useful metal products. These centers focus on melting and casting metals, using a selection of strategies to create components that offer several sectors, including automobile, aerospace, and building and construction. By transforming raw metal ores, scrap metal, and alloys into exact sizes and shapes, shops allow makers to produce top notch products tailored to details applications.

Metal shops add considerably to the economic situation by cultivating and offering work advancement in metalworking innovations. They frequently spend in research and development to boost performance and sustainability, decreasing waste and power usage throughout production procedures. The ability to generate complex geometries not only fulfills style requirements however additionally improves general item efficiency. Essentially, steel shops act as a crucial link in the supply chain, ensuring the accessibility of important metal elements for a myriad of applications in modern-day production.

Essential Processes Entailed in Metal Casting

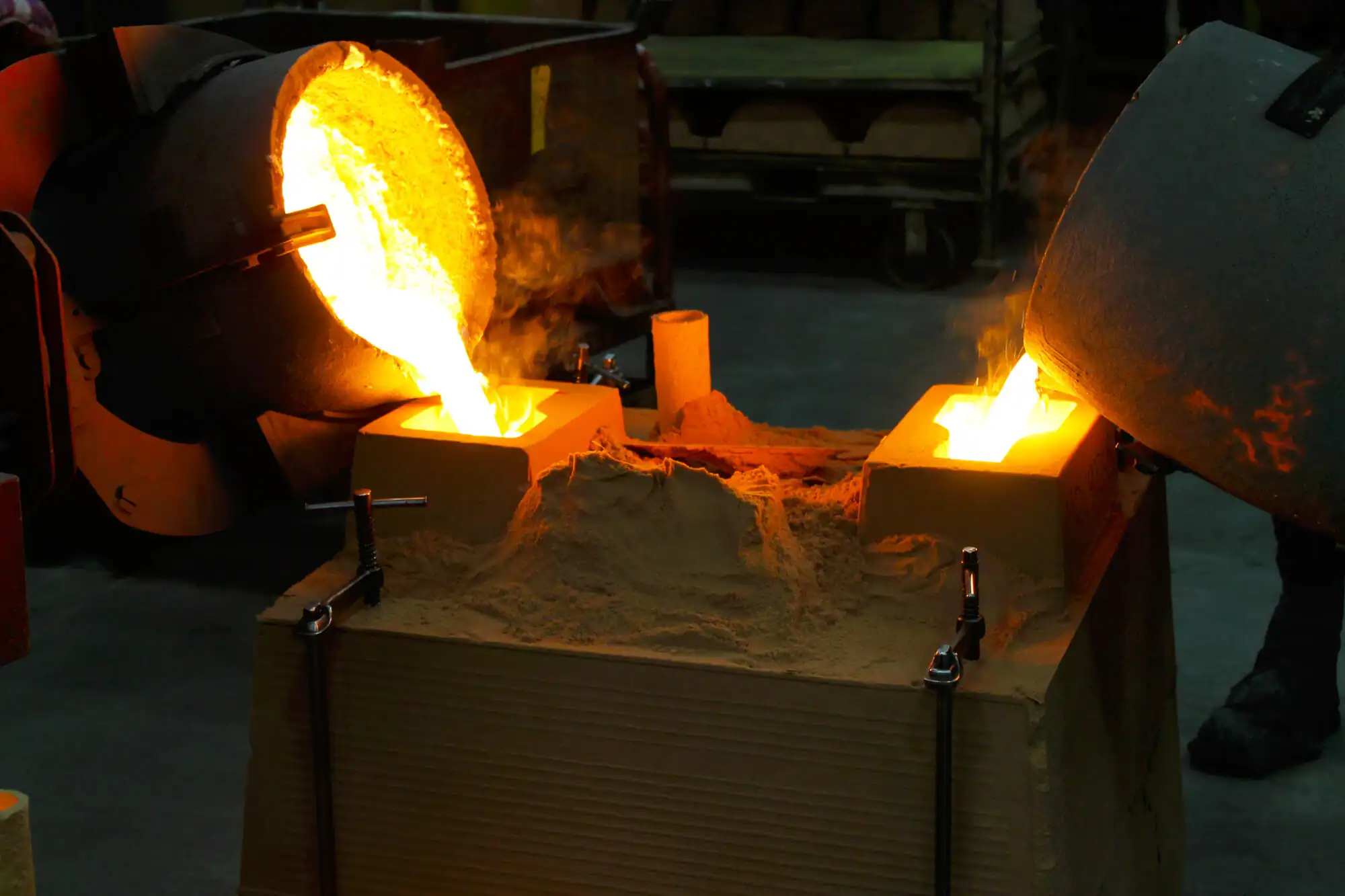

In the procedure of transforming basic materials into ended up products, steel casting includes a number of vital treatments that safeguard the production of high-grade components. The procedure starts with the prep work of liquified metal, which frequently includes melting raw materials in a heater. Once the metal reaches the wanted temperature level, it is put into a mold and mildew shaped to form the end product.

Air conditioning follows, where the molten metal strengthens within the mold and mildew, taking on its brand-new form. After sufficient air conditioning, the mold and mildew is removed, exposing the cast component. This is typically complied with by finishing procedures, consisting of machining, to attain exact measurements and surface quality. Additionally, evaluations are conducted to ascertain that the spreadings fulfill specified standards and resistances. These important procedures highlight the elaborate nature of metal casting, emphasizing the critical duty that each action plays in creating dependable and resilient steel products.

Types of Metals Frequently Used in Factories

While different steels can be made use of in shops, a number of stand apart because of their distinct properties and suitability for particular applications. Iron, particularly in the form of actors iron, is renowned for its stamina, durability, and exceptional casting qualities, making it suitable for equipment and vehicle components. Light weight aluminum is preferred for its light-weight nature and resistance to rust, often made use of in aerospace and transportation industries. Copper alloys, such as bronze and brass, are picked for their phenomenal conductivity and visual charm, typically located in electrical elements and attractive items. Steel, especially carbon steel, is valued for its sturdiness and flexibility, widely utilized in construction and manufacturing. Finally, magnesium is valued for its reduced density and high strength-to-weight proportion, making it a favored choice in applications calling for light-weight materials. Each of these metals uses distinct advantages that accommodate the diverse requirements of different markets.

Quality Control Steps in Metal Factories

Quality control measures in metal factories are important for guaranteeing product stability and conformity with industry criteria (Aluminum Casting). Numerous assessment strategies are used to analyze the properties of actors steels, while adherence to established requirements and certifications enhances quality control. This methodical approach not only enhances functional performance however likewise constructs client count on the last products

Examination Techniques Overview

Reliable evaluation techniques are vital for keeping high requirements in steel factories, as they assure that each product fulfills specified resistances and efficiency requirements. Different techniques are used to analyze the top quality of spreadings, including aesthetic examinations, dimensional checks, and non-destructive testing (NDT) Visual inspections allow operators to determine surface flaws such as cracks or inclusions, while dimensional checks verify that parts comply with make requirements. NDT techniques, such as ultrasonic and radiographic screening, offer much deeper insights right into internal flaws without harming the product. Furthermore, automated evaluation systems are progressively made use of to enhance precision and performance. Together, these evaluation strategies play a considerable duty in securing item reliability and consumer satisfaction within the competitive landscape of steel shops.

Standards and Certifications

In the domain of steel factories, adherence to established criteria and accreditations functions as a keystone for quality control steps. These standards, such as ISO 9001 and ASTM, give frameworks that guarantee consistent product high quality and reliability. Qualification procedures include extensive assessments, including audits and assessments, confirming that foundries meet details efficiency criteria. Conformity with these criteria not just enhances item integrity however also fosters consumer trust and satisfaction. Additionally, qualification can open brand-new markets, as several sectors need compliance for procurement. By executing these high quality control steps, metal shops can decrease flaws, optimize manufacturing procedures, and preserve an one-upmanship in the sector. On the whole, certifications and criteria play a crucial function in guaranteeing the success and sustainability of metal factories.

Developments and Technologies in Factory Workflow

As the need for accuracy and performance in metal spreading proceeds to expand, factories are progressively embracing technologies and modern technologies that enhance their operations. Automation plays a pivotal role, with robot systems simplifying procedures such as mold handling and spreading. This not just minimizes labor expenses but likewise minimizes human mistake, resulting in improved product quality.

In addition, developments in computer-aided layout (CAD) and simulation software application allow shops to enhance layouts before production, enabling faster turnaround times. Including 3D printing technology for creating mold and mildews and cores further increases production and enables for complicated geometries that typical methods can not accomplish.

The integration of information analytics and the Net of Points (IoT) offers real-time surveillance of tools and processes, enhancing predictive maintenance and operational performance. These advancements jointly add to a more responsive, nimble, and competitive factory atmosphere, placing them well to satisfy advancing market needs.

Financial Influence of Steel Factories on Neighborhood Neighborhoods

The improvements in modern technology within steel foundries not just boost production capacities however additionally considerably influence neighborhood economies. Steel shops work as a significant resource of work, giving work for experienced workers and contributing to the economic stability of their regions (Aluminum Foundry). These facilities often stimulate regional organizations, as they need a series of services and products, from raw materials to transport and logistics. The existence of a steel foundry can additionally bring in associated markets, cultivating a network of suppliers and sustaining businesses that flourish in closeness to producing hubs

Moreover, shops add to the tax base, producing revenue for local governments that can be utilized for civil services and facilities renovations. The financial ripple result includes community development, as foundries often participate in neighborhood efforts and support labor force training programs. Generally, steel shops play a crucial duty in bolstering the economic landscape of their areas, ensuring growth and sustainability.

Sustainability Practices in the Steel Factory Market

The metal factory industry is progressively taking on sustainability directory practices to minimize its ecological footprint. Secret methods consist of recycling metal scrap, carrying out energy effectiveness steps, and utilizing green casting processes. These efforts not only add to source preservation yet also improve the industry's general sustainability profile.

Recycling Metal Scrap

Recycling steel scrap stands as a cornerstone of sustainability practices within the metal foundry industry. This process not only saves natural sources however additionally substantially minimizes garbage dump waste. By recovering scrap steel, shops can lower the demand for virgin products, decreasing ecological impact and energy consumption related to mining and extraction. The recycling of metal scrap promotes a round economic climate, where products are recycled and repurposed, developing a much more sustainable production cycle. Shops often implement advanced sorting and handling modern technologies to improve recycling efficiency, ensuring high-quality result. As the sector significantly prioritizes environmentally friendly practices, the recycling of steel scrap stays a crucial component, advertising both economic feasibility and environmental stewardship for future generations.

Energy Performance Actions

Sustainability in the steel foundry sector prolongs past recycling practices to include power efficiency actions. Factories are significantly adopting modern technologies that decrease power intake during steel manufacturing and spreading. Applying innovative melting strategies, such as induction melting, enables more accurate temperature control and reduced energy waste. Additionally, optimizing furnace procedures via warm recuperation systems catches and recycles excess warm, significantly reducing overall power needs. The combination of energy-efficient lighting and automation additionally boosts functional effectiveness. By buying these power efficiency actions, foundries not just reduce their carbon impact however also realize expense financial savings, contributing to a much more economically practical and lasting market. Adopting such techniques is crucial for satisfying regulatory requirements and resolving growing environmental worries.

Eco-Friendly Spreading Processes

While conventional casting methods have served the metal foundry market for decades, environment-friendly casting procedures are currently obtaining prestige as an important component of sustainable manufacturing. These innovative techniques prioritize the decrease of waste, power intake, and damaging discharges. Lots of factories are adopting recyclable products and water-based coatings, lessening environmental effect. Additionally, improvements in 3D printing modern technology help with extra reliable layouts, lowering the need for substantial material use. Closed-loop systems are likewise being executed, permitting the recycling of metals and other by-products. By welcoming these eco-friendly techniques, steel shops not just improve their functional efficiency but also contribute to the worldwide effort towards sustainability, straightening with boosting customer need for eco accountable products.

Often Asked Concerns

What Security Steps Are Implemented in Steel Factories?

Safety and security procedures in metal factories consist of personal safety equipment, correct ventilation systems, normal safety and security training, danger communication, emergency reaction methods, and routine tools maintenance to lessen risks connected with heats and harmful materials.

Exactly How Do Shops Manage Hazardous Products?

What Prevail Job Opportunities in Metal Foundries?

Typical occupation possibilities in steel shops consist of roles such as factory professional, melting driver, quality assurance inspector, upkeep designer, and manufacturing supervisor, each contributing to the efficient procedure and outcome of metal casting processes.

Just How Do Shops Manage Waste and Recycling?

Shops handle waste and recycling useful source via systematic procedures, including the collection of scrap metal, reusing materials, and carrying out eco-friendly methods (Metal Foundry). These approaches assist minimize ecological influence while promoting resource performance within the sector

What Are the Ecological Regulations for Steel Foundries?

Metal factories play an essential duty in the production sector by transforming raw materials right into useful metal products. Quality control steps in metal factories are necessary for guaranteeing item stability and conformity with market criteria. By executing these high quality control measures, steel factories can reduce issues, enhance manufacturing processes, and keep an affordable edge in the market. Reusing metal scrap stands as a foundation of sustainability methods within the steel foundry industry. While traditional spreading techniques have served the steel factory market for years, green casting processes are now obtaining prominence as a crucial component of lasting production.